Machines & Applications

Our machines & equipment to support your manufacturing.

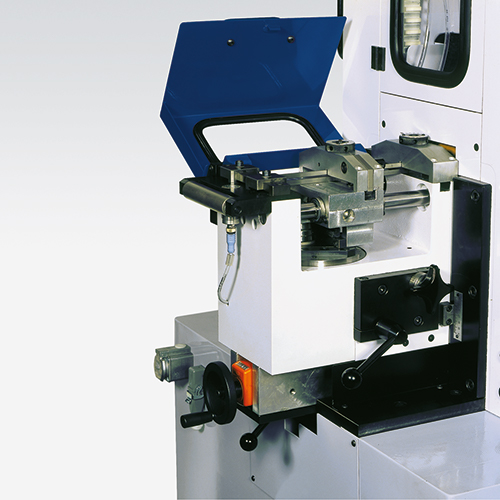

SEP Series

120 - 1000 kN

The modular design of the SEP series offers possibilities and combinations for a wide range of applications. This is particularly interesting for any production tasks.

The simple use of changeover devices, controlled setup processes, and the customized design of the press to meet customer requirements all contribute to improved efficiency, cost savings, and flexibility. This in turn leads to a significant increase in your competitiveness.

Speed

High-speed punching machine up to 800 strokes/min Modular

Modular

Modular design for integration into customer-specific production lines; integration of an additional punching unit for secondary operation

Maximum performance

Multi-track lamella forming possible for maximum performance

Ready to use

Ready-to-use production solutions that include unwinding, stacking, feeding equipment such as rollers and grippers, tooling and sound insulation, etc.

Feed systems

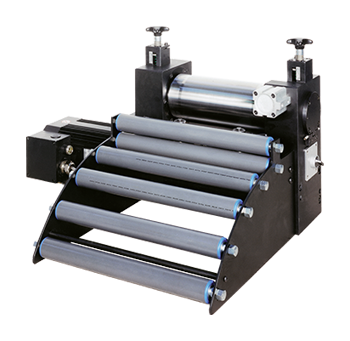

Dynamic Roller Feed SWV

With the feeders, the system chain from the coil line to the press is complete for highly productive use. With a feed rate of up to 120 m/min for the roll feeders and an accuracy of up to 0.02 mm, as well as minimized setup and set-up times, your press is well equipped.

Stable structure, high precision and repeatability

Off-center tape transport possible

Hardened and ground feed rollers, optionally plastic/rubber

Integrated feed control with easy programming

Pneumatic intermediate ventilation, on request also mechanical forced ventilation for high stroke rates

Can be mounted variably on the left or right side of the press or on the rear side of the press, as well as on automatic punching presses and systems from other manufacturers

Strip widths according to customer requirements up to 1000 mm

One contact for press and feed

High-Performance Gripper Feed SZV

Simple and fast adjustment of the feed length and sheet thickness with high feed accuracy characterize the SZV mechanical gripper feeders. The gripper feeders can be attached to all SEP presses (optionally left, right).

Compact, robust design

Fully mechanical, positively controlled sequence for high stroke rates

Strip thickness guide over the entire feed length

Intermediate ventilation can be switched on and off and is infinitely adjustable

Adapted to SEP series

Stroke rates of up to 800 strokes/min

Belt speed up to 30 m/min

Feed height adjustment up to ±30 mm possible

Feed duration 180

Feed accuracy up to 0.01 mm

Feed easily adjustable to different tools and strokes

Applications for which our machines & equipment are used.

Application examples

Our stamping presses and the system solutions developed from them form the basis for flexible, rational and cost-efficient production in many industries such as:

Automotive Supply Industry

Electronic parts manufacturing industry

Construction industry for mechanical devices

Manufacturing industry for medical parts

Consumer goods industry

Seals for e.g. the food industry

Our stamping systems are used to manufacture the following products, among others:

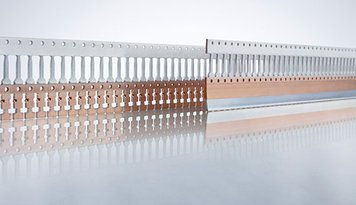

Cooling fins

Film

Link to Youtube

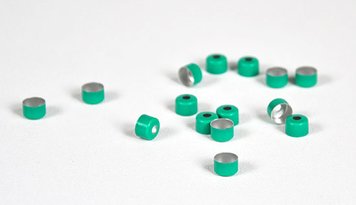

Electrical contacts

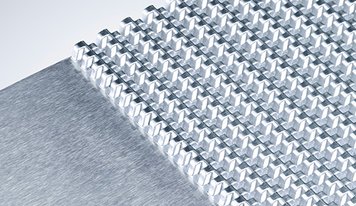

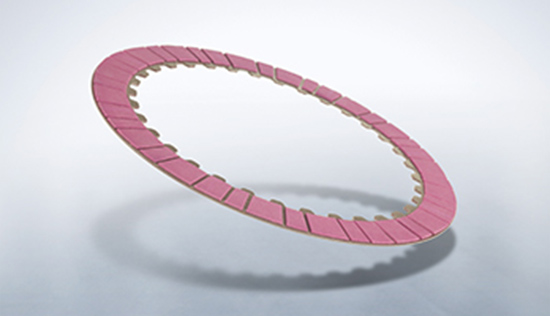

Gear grinding rings

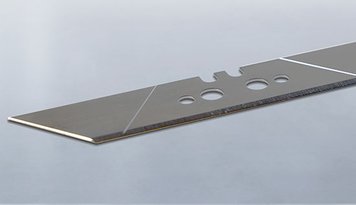

Band saw blades

Razor blades